Connections

Different regions of the world have established their own standards, e.g., British Standard (BS), German Standard (DIN), Japanese Standard (JIS), French (AFNOR) and so on. All different cylinder valve outlet standards separate gases based upon pressure and chemical property. Standardization of cylinder valve outlet connections is important to ensure product safety and integrity.

There are three basic groups of valve outlet connections:

1. Connections for general, industrial compressed gases (mostly threaded connections).

2. Connections for ultra-high integrity gases.

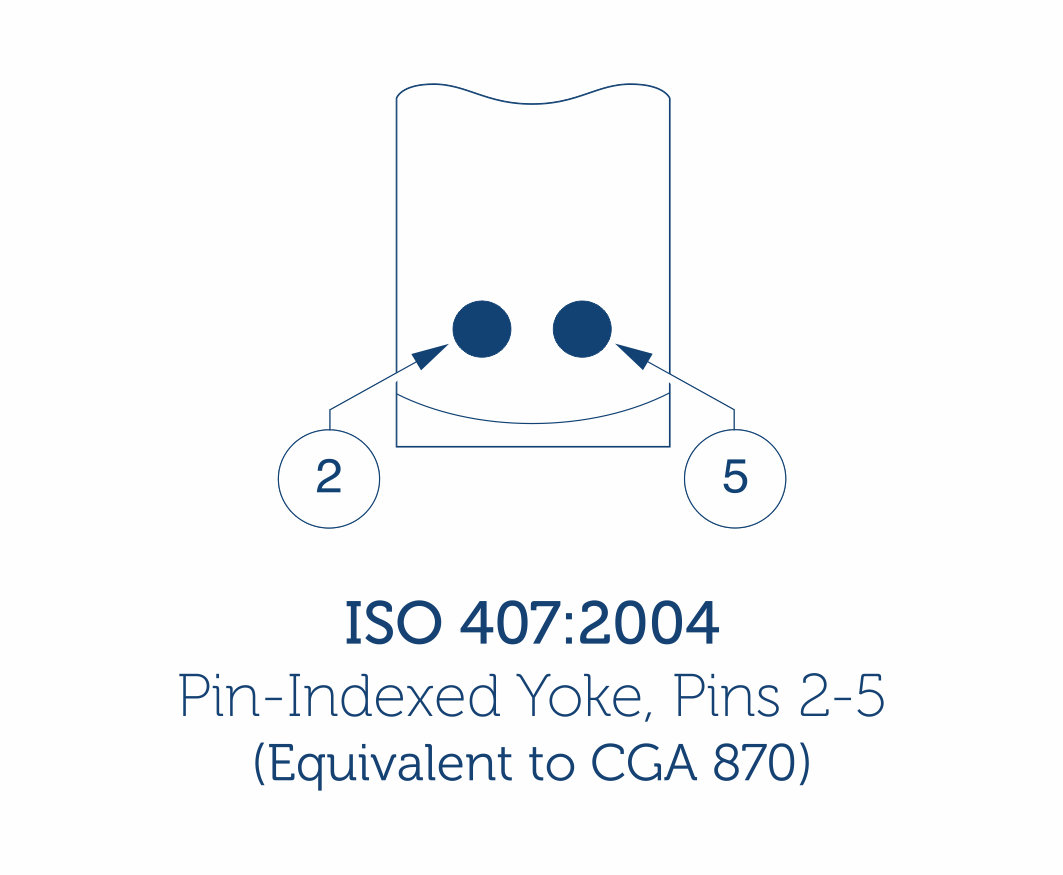

3. Pin-Indexed connections for medical gases.

For our medical gases we strongly recommend the use of the Pin Index Safety System. The Pin Index Safety System is designed to minimize the ability to inadvertently connect a cylinder to a system that may not be compatible with the gas or cylinder pressure, or that may contain a gas that would be unsafe.

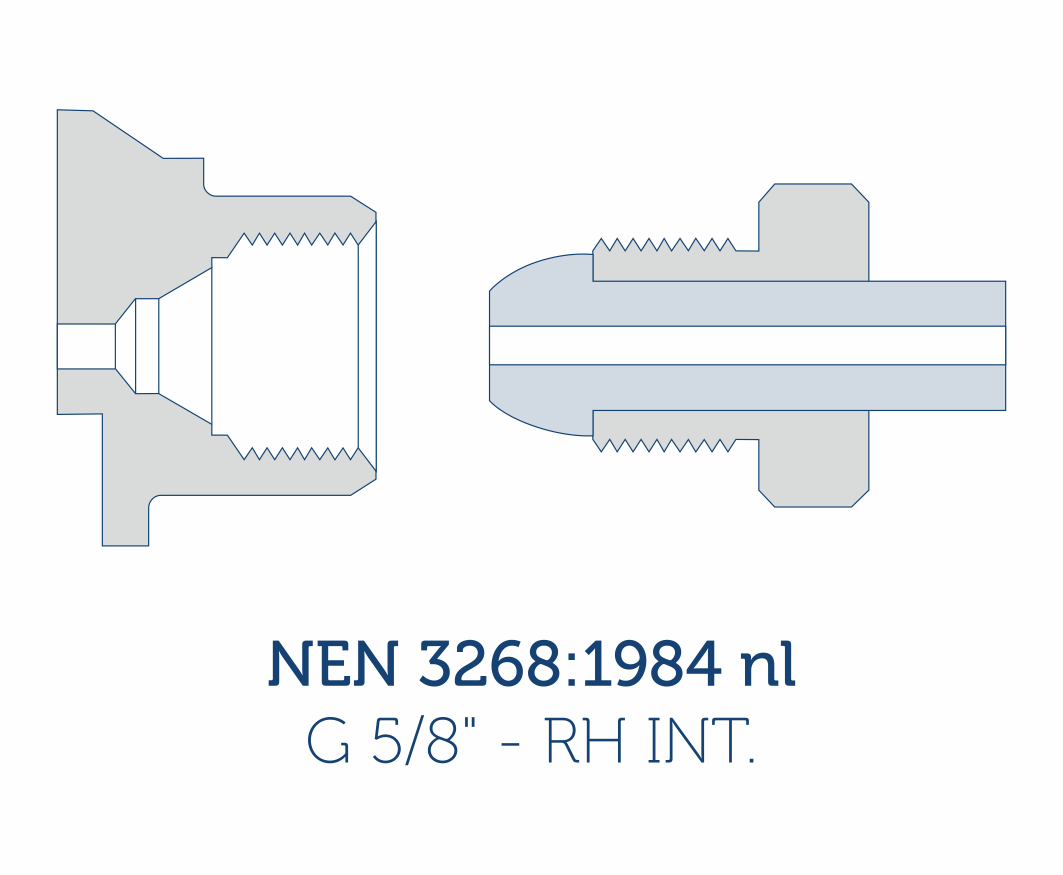

If required, we can supply cylinders with a threaded connection. Our threaded connection is in accordance with the NEN 3268:1984 standard and as a third option, we also supply medical oxygen cylinders with an integral valve.

Cylinders with a different valve outlet connection are only available upon request and is strongly discouraged.

The Pin Index Safety System (PISS) is a precise configuration of pins and holes that facilitate the connection between a specific medical gas cylinder and the delivery system (regulator) of these gases. Each Pin Index Safety System has six possible pin placement sites, depending on the gas within the cylinder. Pin Index Safety System is specifically intended for use with medical gases.

The NEN 3268 standard, is a thread connection, which was adopted in 1984 by the The Royal Netherlands Standardization Institute (NEN). The NEN 3268:1984 describes the principal and mating dimensions of valves, nipples and coupling nuts for use on gas cylinders for industrial purposes. This type of connection is accepted for the use with medical gases, but has not been specifically developed for this purpose.

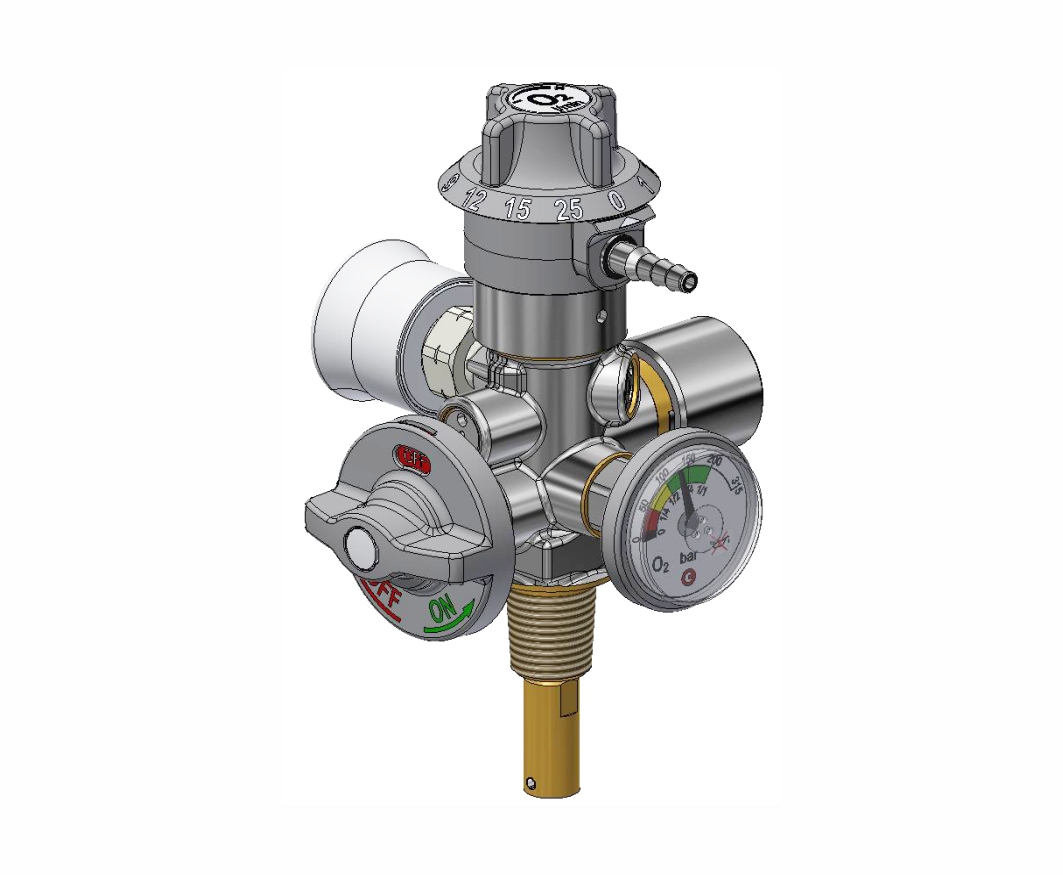

The Integral Cylinder Valve is a built in pressure regulator with an easy on/off handwheel and integral flow selector. It is designed to make cylinder operation and the task of medical gas administration easier, as there is no need to attach a regulator. The integral valve has an AFNOR full flow outlet for use with a demand valve. The integral valve cylinders distributed by MedOx Marine are constructed from aluminum.

Residual Pressure Valve (RPV)

All cylinders are equipped with a Residual Pressure Valve. The Residual Pressure Valve (RPV) retains a small positive pressure (1-5 Bar) in a gas cylinder even if the valve is inadvertently left open. Therefore preventing the possibility of back contamination and maintaining a high gas quality. The use of a Residual Pressure Valve also reduces the risk of moisture ingress into the cylinder. Moisture ingress can cause corrosion and stress corrosion cracking (SCC), which can lead to cylinder failure through leakage or burst.

Reducing Health & Safety Risks by Replacement

MedOx Marine carries the responsibility to maintain the quality of the gas cylinders and the medical oxygen gas, therefore preventing impurity of the medical oxygen gas and the possible risk of bacterial contamination inside gas cylinders. This is why we always supply a new pre-filled cylinder, which also eliminates the maintenance interval, every 5 or 10 years (depending on Flag State requirements), for the required hydrostatic test. In order to guarantee the quality and integrity of the gas and therefore preventing possible health and safety risks, it is prohibited by the customer to refill the medical oxygen cylinder.

Medical Oxygen Gas Life Span

The life span of the medical oxygen gas is at least 30 months with a maximum of 36 months.

MedOx Marine oxygen cylinders will be clearly marked with the expiry date of the medical oxygen gas inside the cylinder. The expiry date can also be checked via the provided MedOx Supply Certificate.